The components used in today’s precision assemblies require an extremely high degree of cleanliness. Ultrasonic technology has provided a highly effective way to meet these precision cleaning needs. Sophisticated ultrasonic cleaning technologies are used in the most demanding applications to remove sub-micron particles from components used in disc drive, aerospace, electronics, medical devices, and many other critical industries.

Understanding ultrasonic cleaning begins with looking at the science behind it. This article will discuss some of the basic concepts involved in understanding how ultrasonic cleaning works.

What are Ultrasonic Waves?

The vibration of an object creates sound waves that cause vibration of other molecules that are in contact with that object. As those vibrations travel through a sound conducting media, they in turn cause vibrations which are transmitted throughout the media. In the case of vibrations in air, our ears detect these vibrations and the brain interprets them as sound. A healthy ear can hear sounds of very low 20 Hertz frequency, to a very high frequency of 20,000 Hertz. (For an interesting range demonstration, try the audio test found here.)

Sound waves at a frequency of 20,000 Hz or higher are considered ultrasonic waves.

How Are Ultrasonic Waves Transmitted During Ultrasonic Cleaning?

Cleaning Technologies Group is excited to be an exhibitor at the 2019 Precision Machining Technology Show, the must-attend event for users of precision machining equipment and services related to machine tools, cutting tools, work handling, materials, parts cleaning, and more.

PMTS / PCx 2019 is scheduled to take place April 2 – 4, 2019 in Cleveland, Ohio. Visitors to CTG Booth #11075 will be introduced to innovative new products, technologies, and services. Featured among the new technologies exhibited at the show will be:

New LeanJet® RB-1 Cleaning System

This systems uses a patented washing and rinsing process of agitation, spray impingement, hydraulic purging through immersion and rotation, ultrasonics, and heated blow-off drying. The patented "triple action" batch cleaning process was developed specifically to process a broad range of challenging parts, especially those with internal bores and passages and complex geometries, making this system capable of meeting critical cleaning expectations.

Looking for ways to increase process efficiency and productivity? Automating your parts washing process is a great way to implement simple, but significant improvements.

If you have considered the idea of automated parts washing but thought it would be complicated or cost-prohibitive, now is the time to revisit the idea! CTG can do custom engineered solutions and has several highly flexible approaches to automating your parts washing process to realize significant cost savings and efficiency gains.

Robot Pick and Place

This set up would involve a part that is coming off of a process line, a machine center or off of a cueing pallet. The robot can be placed on the conveyor line or in the washer, where it will both position the part for washing and then place it into the next station in the process.

Tie Washer into a Flow Line

This option positions the washer within an automated flow line coming out of a machining center. Parts are automatically placed on a belt or other means of transport directly following an automated machining process. Robotic automation puts the parts in place for the next step in the process.

Parts Washing Nozzles on a Robot and Stationary Nozzles Designed to Work with Robots

CTG is excited to participate in Photonics West 2019, to be held in San Francisco, California, February 5 - 7, 2019. Photonics West is the leading global event for the photonics and laser industries. As a recognized leader in ultrasonic technology, we will be demonstrating a number of new products in Blackstone-NEY Ultrasonics Booth #5647.

Among the new technologies exhibited at the show will be:

Megasonics

Megasonics is a multi-frequency, sweeping or non-sweeping system. The multiMEG's four mode operation (430 kHz conventional streaming Megasonics / 430 kHz dualSWEEP® Megasonics / 1.3 MHz conventional streaming Megasonics / 1.3 MHz dualSWEEP® Megasonics) delivers higher yields in a single process tank. Combining our multiMEG technology with our advanced plate arrays and submersible designs allows integrators and existing users the ability to experience higher particle removal efficiencies while minimizing downtime associated with full module replacement.

Medical Design & Manufacturing (MD&M) West 2019 is scheduled to take place February 5 - 7, 2019 in Anaheim, California. MD&M West is the place for professionals in the global medical manufacturing community to learn about the latest advances in the medtech industry. In addition to more than 1,900 suppliers showcasing the latest solutions in contract manufacturing, manufacturing equipment, automation, R&D, medical device components, materials, plastics, and more, MD&M West hosts the largest three-day medtech conference in North America.

Medical Design & Manufacturing (MD&M) West 2019 is scheduled to take place February 5 - 7, 2019 in Anaheim, California. MD&M West is the place for professionals in the global medical manufacturing community to learn about the latest advances in the medtech industry. In addition to more than 1,900 suppliers showcasing the latest solutions in contract manufacturing, manufacturing equipment, automation, R&D, medical device components, materials, plastics, and more, MD&M West hosts the largest three-day medtech conference in North America.

As a parts cleaning solutions supplier to the medtech industry, CTG is excited to be participating in this year’s event. Attendees who visit the Blackstone-NEY Ultrasonics Booth #1354 will learn about our products, technologies, and services. Among the new technologies exhibited will be:

The New Blackstone-NEY Ultrasonics Stainless Steel GMC Series Cleaning System

Ransohoff, a leading name in cleaning technology, will be featured in the upcoming SHOT Show Week Supplier Showcase, happening January 21 -22, 2019, in Las Vegas, NV. The SHOT Showcase is a dedicated event for suppliers to present products and solutions to shooting, hunting, and outdoor industry manufacturers. Producers of parts, components, and assemblies for the shooting sports or outdoor sporting market will have the opportunity see new Ransohoff drum cleaning systems tanks, as well as many other parts cleaning solutions.

Innovative cleaning solutions to be featured at SHOT Show in Ransohoff Booth S1720 include:

The ultrasonic cleaning process uses a combination of ultrasound and water and/or parts cleaning solvent to clean a wide variety of component parts and assemblies. Ultrasonic cleaning is especially effective for delicate or complex parts.

The ultrasonic cleaning process uses a combination of ultrasound and water and/or parts cleaning solvent to clean a wide variety of component parts and assemblies. Ultrasonic cleaning is especially effective for delicate or complex parts.

During the ultrasonic cleaning process cavitation bubbles induced by high frequency sound waves are used to agitate the parts cleaning liquid. The agitation releases contaminants adhering to substrates such as plastic, metal, glass, ceramics, and rubber. The ultrasonic cleaning process allows the cleaning solution to penetrate blind holes, cracks, and recesses is to thoroughly remove all traces of contamination tightly adhering or embedded onto solid surfaces.

While ultrasonic cleaning is highly effective, the issue of “ultrasonic shadowing” can impair the thoroughness of this type of cleaning. Ultrasonic shadowing occurs when the parts being cleaned are positioned in a manner that casts an “ultrasonic shadow” on some of the other parts. This shadow prevents covered parts from being effectively cleaned. Though ultrasonic shadowing is known to occur, it can be difficult to define and predict.

Unlike the shadow cast by a solid object illuminated by the sun or a lightbulb, an ultrasonic shadow is not distinct in shape. Ultrasonic shadows are more like the shadows cast by diffused light, like the sun shining on a cloudy day, where the darkened area is less distinctly defined.

Ransohoff Washmaster Cabinet Washers Offer Flexible, Cost-Efficient Solution

Ransohoff Washmaster Cabinet Washers Offer Flexible, Cost-Efficient Solution

Ransohoff, a division of Cleaning Technologies Group, offers a comprehensive standard line of cabinet washers, including our Washmaster line of cabinet washers.

Utilizing spray technology, Washmaster cabinet washers are efficiently used in a wide range of industries and require minimal engineering to suit your application needs. The Washmaster series provides a highly effective and extremely cost competitive cabinet-type parts washer solution.

Washmaster CW-23-R / CW-35-R

The CW-Series Washmaster rotary table spray washer is an ideal point of use cabinet washer. A a perfect solution where minimal space is available, the CW series is very robust in construction and offers a platform that is pre-engineered, cost competitive, and ready for delivery.

CTG will be exhibiting many innovative cleaning systems at the upcoming IMTS conference to be held in Chicago, Illinois. Among the technologies displayed will be the LeanVeyor® Conveyor Washer system. Unlike typical conveyor washers, which have a reputation for inefficiency, our LeanVeyor parts washer has been developed to be the most energy efficient, conveyor cleaning system available today.

CTG will be exhibiting many innovative cleaning systems at the upcoming IMTS conference to be held in Chicago, Illinois. Among the technologies displayed will be the LeanVeyor® Conveyor Washer system. Unlike typical conveyor washers, which have a reputation for inefficiency, our LeanVeyor parts washer has been developed to be the most energy efficient, conveyor cleaning system available today.

Developed specifically for lean manufacturing, the LeanVeyor requires minimal floor space while providing exceptional cleaning and drying performance. Using common sense approach to component choice and placement, the LeanVeyor offers quick and efficient access and servicing. All stages are insulated and compartmentalized with exhaust dampers that adjust individually, reducing system heat loss.

The entire unit has been engineered and fabricated to be flexible, durable, simple to use and easy to maintain.

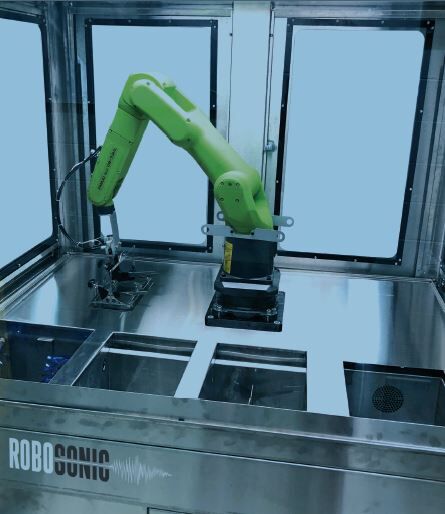

Blackstone-NEY Ultrasonics is excited to debut the newest of our many innovative cleaning technologies at the upcoming IMTS conference. Our exhibit will provide attendees with a first look at our new Robosonic Robotic Precision Cleaning Cell.

Blackstone-NEY Ultrasonics is excited to debut the newest of our many innovative cleaning technologies at the upcoming IMTS conference. Our exhibit will provide attendees with a first look at our new Robosonic Robotic Precision Cleaning Cell.

The Robosonic Cleaning Cell is a four-tank system that includes a spray wash, ultrasonic immersion wash, ultrasonic rinse tank and dryer. The robotic operation is provided by a Fanuc CR-7i. Fanuc is a trusted industry leader in robotic technology.

Robosonic features include:

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom